Omer Mustapha1*, Shumaila Shafique1

1. Dow College of Pharmacy, Faculty of Pharmaceutical Sciences, Dow University of Health Sciences, Karachi.

*Corresponding author: omer.mustapha@duhs.edu.pk

ABSTRACT

Background: The main object of this study is to produce flurbiprofen-loaded microspheres by electrospray technology to achieve the effect of micronization and amorphous systems, thus increasing the water solubility and oral bioavailability of non-aqueous drugs.

Method: Microspheres were prepared using an electrospray machine equipped with a stainless steel tip (21G). Flurbiprofen and polymer PVP were entirely dissolved with in solvent (0.1M NaOH alkaline ethanol) & electrosprayed using operating parameters of eleven kilovolts voltage, flow rate of 0.09 ml/h, and 20 cm collector distance. Electrosprayed products are characterized by SEM, DSC, PXRD and FTIR. Perform solubility, and dissolution tests with flurbiprofen powder.

Results: SEM images show that the flurbiprofen drug-loaded microspheres are spherical, with a geometric diameter of approximately 1.3 μm and a drug loading rate of approximately 70%. DSC and PXRD presented the amorphous structure of drug in microspheres, while FTIR proved the stability of drug in a solid state. The in vitro solubility of electrospray microspheres is 150 times higher than that of flurbiprofen powder, and the dissolution is 4 times greater.

Conclusion: From the above analysis and results, electrospray technology can be used to produce highly soluble drug microspheres, which are effective in increasing the solubility and oral bioavailability of drugs.

Keywords: Flurbiprofen, Drug Microspheres, Electrospray Technology

Introduction:

Electrospray (electro-hydrodynamic spray) produces material by using electro-hydrodynamic force to disperse liquid into fine jets. This technology appears to accelerate and produce particles from micro to nanoscale. By optimizing the flow rate and voltage, electro-hydrodynamic technology can not only achieve the precise morphology of the product but also improve drug release (1, 2).

Electro hydrodynamics is the driving force in the design of DDS (drug delivery systems). Its good features are that the drug is easy to transport to the truck, high loading capacity, high encapsulation performance, ease of management, open air application in compact units, high pressure and affordable price (1, 3).

Electro-hydrodynamic technology can be divided into the following tasks: 1. Payment of the liquid 2. Construction of the conical jet 3. Refinement of the jet in the presence of electric field 4. Instability of the plane 5. Collector of solidified fibers (4).

The doctrine of electro-hydrodynamic is application of electric field that intensifies the liquid meniscus at the tip of the metallic nozzle. When the electric current is high enough, the liquid meniscus forms a cone-like plane (also known as a Taylor cone) that is further divided into droplets by electrostatic forces (5). Electro-hydrodynamic technology can be widely used in research and industry. The technology is used for micro- or nanocapsule development, micro- or nanoparticle production, and micro- and nanofilm deposition. This can be used to create new drug delivery systems, as well as in the cosmetic and food industries (2).

Flurbiprofen is a nonsteroidal anti-inflammatory medication (NSAID) which belongs to the phenyl alkanoic acid derivative class. It is used for the treatment of osteoarthritis and its related sign and symptoms or rheumatoid arthritis. The recommendation of the initial dose of flurbiprofen is 200-300 mg/day, which is divided into two, three, or four doses each day. However, at pH 7.0, it dissolves somewhat in water while it dissolves rapidly in the majority of polar solvents. Therefore, to be more bioavailable and effective this drug needs to have good aqueous solubility.

This research aims towards the solubility enhancement of flurbiprofen by loading it into hydrophilic polymer by electro spraying technique.

Nano scale and Micro anisotropy Polymer particles have obtained greater attention because of their capability to simultaneously existing different physio-chemical properties. It was determined that gold nanocrystals (NCs) can be particularly included into one compartment of anisotropic polymer particles (6, 7, 8).

MATERIALS AND METHODOLOGY:

Materials

Flurbiporfen was generously contributed by Whanin Pharm. Co. (Suwon, South Korea), The supplier of polyvinyl pyrrolidone (PVP, K30) was BASF (Ludwigshafen, Germany). While the remaining chemicals and solvents were all HPLC grade and may be utilized purified or not.

Methodology:

Preparation of Flurbiprofen Loaded Microspheres:

A single nozzle electrospraying device equipped with a stainless steel nozzle (21G) was used for creating microspheres. The flurbiprofen and the “polymer” PVP were accurately dissolved in the solvent i.e. 0.1 M NaOH alkalic ethanol and was electro sprayed. The operational parameters that were utilized included an 11 kV voltage, a 0.09 ml/hr flow rate, and a fixed collector at a space of twenty (20) cm.

Aqueous Solubility and Dissolution of microspheres:

The dissolution and aqueous solubility of the fabricated microospheres were performed in comparison to drug powder. The samples were quantified by HPLC system (Agilent 1260). The HPLC system was fitted out with eclipse XDB-C18 column (Agilent 5 µm, 4.6*150 mm). The mobile phase for the HPLC system contained 0.1 M sodium acetate-acetonitrile-triethylamine 61:39:0.05 v/v) pH adjusted to 4 with glacial acetic acid. The mobile phase flow rate was set at 1.5 ml/min, and the lambda max to monitor the eluent was fixed at 230 nm.

Characterization of Fabricated microspheres:

The S-4800 electron microscope, manufactured by Hitachi in Tokyo, Japan, was used to carry out the scanning electron microscopy for the morphological analysis of the flurbiprofen-loaded microspheres.

In order to determine the prepared product’s solid state, differential scanning calorimetry (DSC Q200; TA Instruments, New Castle, DE, USA) was used. A powder X-ray diffractometer (D/MAX-2500/PC; Rigaku X-ray equipment; Japan) was utilized for the analysis of the crystallinity of the nanospheres that were produced.

RESULTS AND DISCUSSION:

By keeping an eye on the characteristics of operation, A technique that can provide repeatable, almost monodisperse size morphologies is electrospraying. A stable cone-jet system, which can be customized by adjusting the spraying solution’s flow rate, conductivity, and field strength, is essential for the consistent creation of particles and nanospheres.

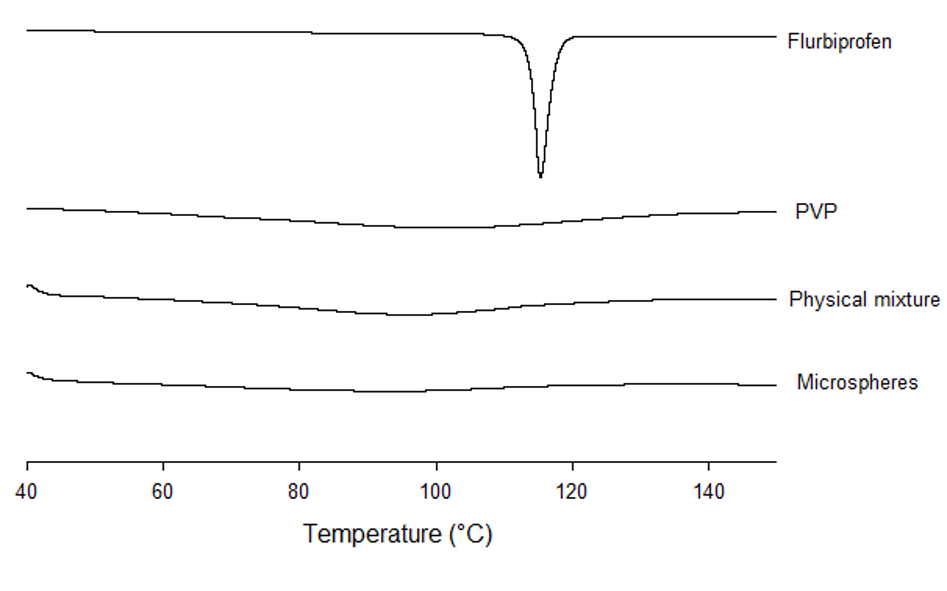

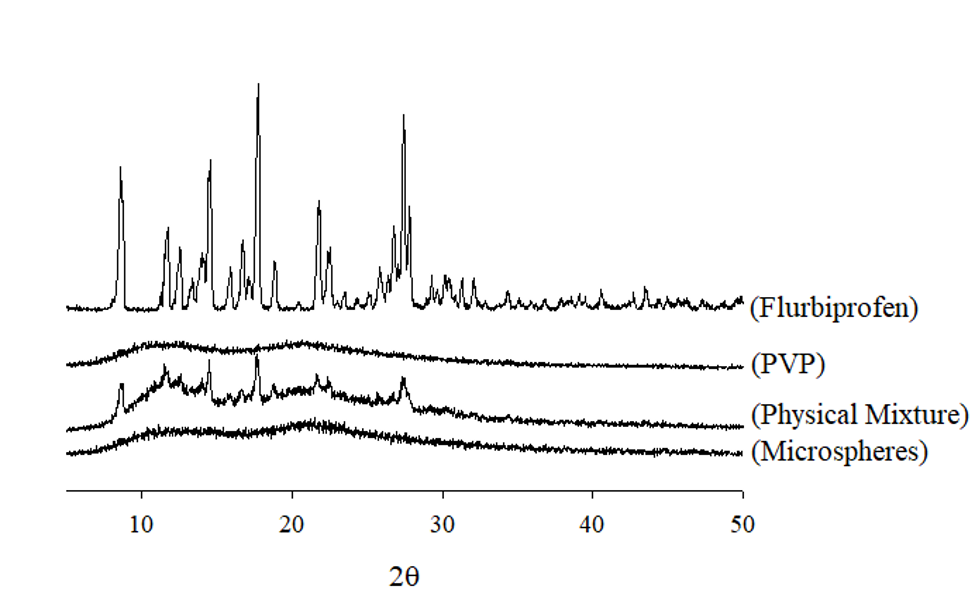

The results of PXRD and DSC presented the amorphous pattern of drug in microspheres fig. 1A.

Figure 1A: DSC profile of drug and prepared microspheres.

Figure 1A: PXRD profile of drug and prepared microspheres.

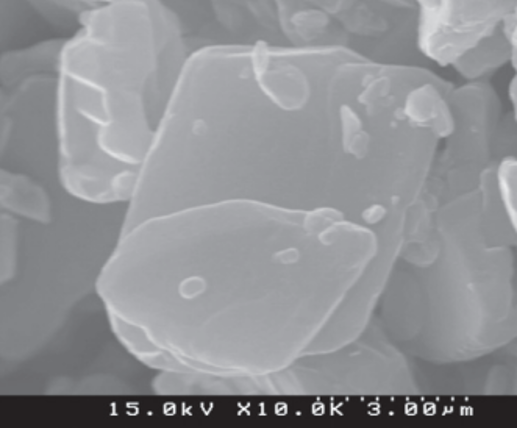

Figure 1A: SEM image of Flurbiprofen.

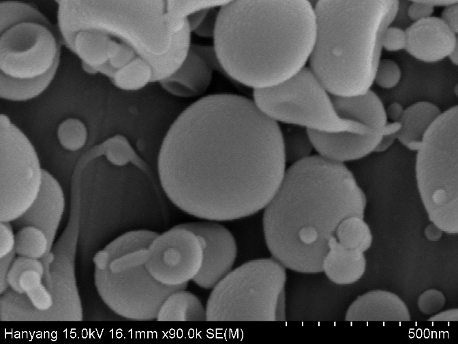

The SEM images showed that the flurbiprofen loaded microspheres were spherical in shape in comparison to the pure powder which shows a crystalline morphology (fig. 2A). It was observed that the microspheres generated were of geometric mean diameter about 1 nm; the drug loading efficiency was around 70%

Figure 2A: SEM image of prepared microsphere

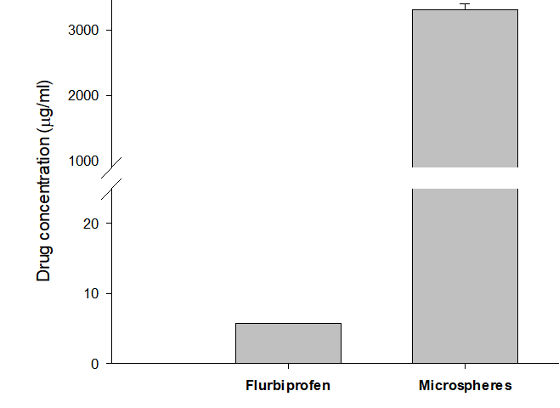

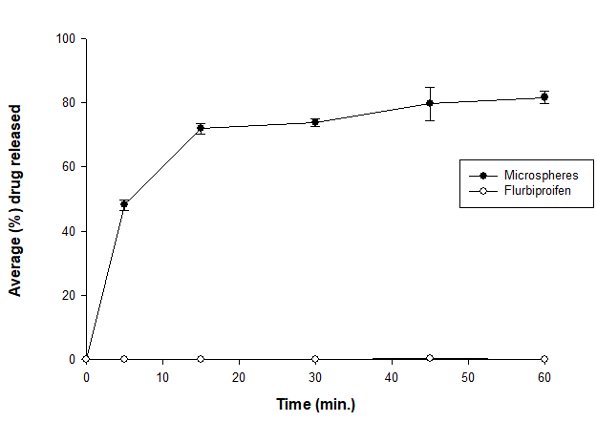

Moreover, the electrosprayed microspheres gave a higher solubility of 150 folds (fig. 3A) and higher dissolution rate of 5 folds (fig. 3B) of the drug in vitro than pure flurbiprofen powder (p= <0.05).

Figure 3A: Aqueous Solubility study.

Figure 3B: In-vitro drug release profile.

CONCLUSION:

It can be concluded based on the observations and results achieved that the electrospraying technique can be used to create drug-loaded microspheres that will aid to improve the oral bioavailability and aqueous solubility of weak aqueous-soluble medicines,

REFERENCES:

- Wu Y, MacKay JA, McDaniel JR, Chilkoti A, Clark RL. Fabrication of elastin-like polypeptide nanoparticles for drug delivery by electrospraying. Biomacromolecules. 2008 Dec 10;10(1):19-24.

- Jaworek AT, Sobczyk AT. Electrospraying route to nanotechnology: An overview. Journal of electrostatics. 2008 Mar 1;66(3-4):197-219.

- Chakraborty S, Liao IC, Adler A, Leong KW. Electrohydrodynamics: A facile technique to fabricate drug delivery systems. Advanced drug delivery reviews. 2009 Oct 5;61(12):1043-54.

- Rutledge GC, Fridrikh SV. Formation of fibers by electrospinning. Advanced drug delivery reviews. 2007 Dec 10;59(14):1384-91.

- Gañán-Calvo AM, Davila J, Barrero A. Current and droplet size in the electrospraying of liquids. Scaling laws. Journal of aerosol science. 1997 Mar 1;28(2):249-75.

- Lim DW, Hwang S, Uzun O, Stellacci F, Lahann J. Compartmentalization of Gold Nanocrystals in Polymer Microparticles using Electrohydrodynamic Co‐Jetting. Macromolecular rapid communications. 2010 Jan 18;31(2):176-82.

- Hwang S, Roh KH, Lim DW, Wang G, Uher C, Lahann J. Anisotropic hybrid particles based on electrohydrodynamic co-jetting of nanoparticle suspensions. Physical Chemistry Chemical Physics. 2010;12(38):11894-9.

- Roh KH, Martin DC, Lahann J. Biphasic Janus particles with nanoscale anisotropy. Nature materials. 2005 Oct 1;4(10):759-63.